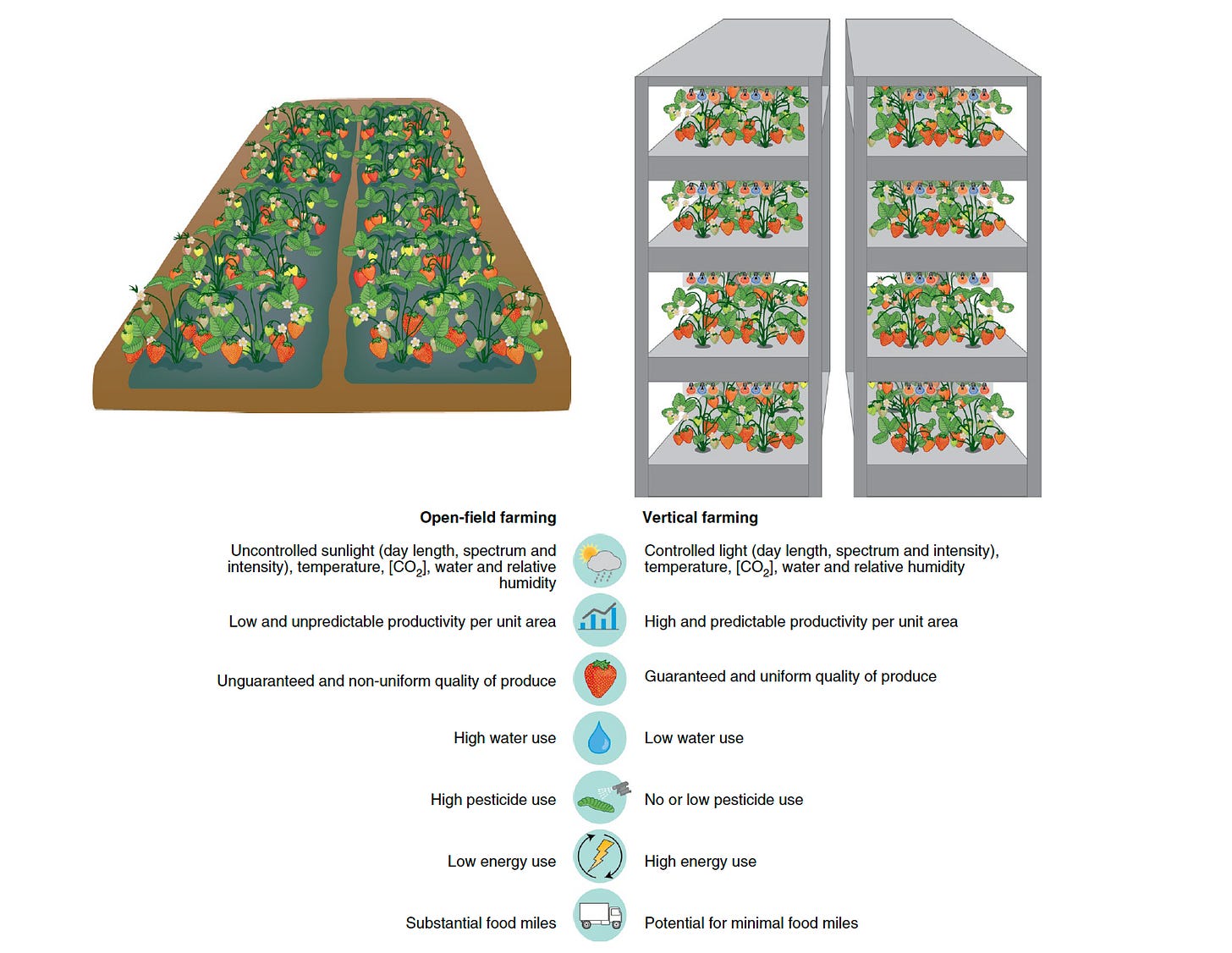

About half of the world’s habitable (desert- and ice-free) land is used for farming. Vertical farming provides an elegant solution: grow crops upwards, rather than outwards.

It can reduce or eliminate the need for pesticides. Temperatures can be optimized. It can make food production far more resilient to extreme weather, which will be increasingly important with climate change.

In an ideal world, it would massively increase food security while reducing the environmental impacts of farming.

What stands in the way is energy demand. Growing crops indoors is energy-intensive. So we’re really swapping a land problem for an energy one. That’s not just a challenge in terms of supplying that energy, but it also makes most vertical farms uneconomical to run. Staple foods would be dramatically more expensive than they are today, and given that billions of people can’t afford a healthy diet now, that’s not a workable solution.

Here, I’ll run through some of the numbers on vertical farming, looking at the energy and financial costs that make me skeptical that this technology will make a dent in global food supplies any time soon.

The economics of producing leafy greens and lettuce in vertical farms can work, if electricity prices are low

Vegetables can fetch higher market prices than staple crops like cereals, which makes the economics a bit more promising. Vegetables often grow in much shorter cycles, which, again, increases production and profitability. They’re relatively short in height compared to cereals, so they take up much less vertical space. Vegetables often require much more controlled conditions to grow well, making them better suited to perfectly controlled vertical farms.

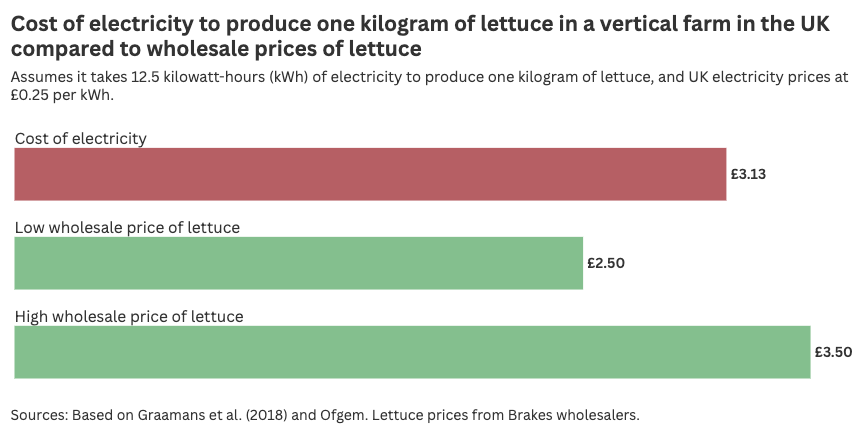

Let’s run the numbers for one example crop: lettuce.

It’s estimated that it takes around 12.5 kWh to produce one kilogram of lettuce.2 Of course, this depends on the specific setup of the farm, so it could range from around 10 to 20 kWh.

What is this energy used for? Most of it — typically 60% to 80% — is for lighting, which essentially mimics the sun to produce the light needed for photosynthesis. The rest is used for heating or cooling — the proportion of each depends on where the vertical farm is located and what crop is being grown. Smaller amounts of energy are used for delivering nutrients, seeding, and other maintenance or processing.

What’s the Difference Between Vertical Farming and Machine Learning?

What’s the Difference Between Vertical Farming and Machine Learning?

How much would this energy cost financially?

In the UK, electricity prices are around £0.25 per kWh. So, one kilogram of lettuce would cost around £3.10 for the energy alone.

That’s about the same as the wholesale or retail price of lettuce, which I can find for around £2.50 to £3.50 per kilogram.

Of course, in addition to energy costs, producers need to finance capital costs and operational costs such as nutrient inputs, staffing, packaging, etc. It’s hard to see how this would break even, let alone actually turn a profit.

Production costs also become very sensitive to changes in energy prices. When electricity prices skyrocketed in 2022 and 2023, so did the cost of vertical farming. Many companies went bust or faced huge employee layoffs because they just couldn’t cover the energy costs.

The numbers make it clear why. During 2023, electricity prices in the UK rose to more than £0.40 per kWh. That means producing a kilogram of lettuce would cost £5 from energy alone. No one can make that profitable.

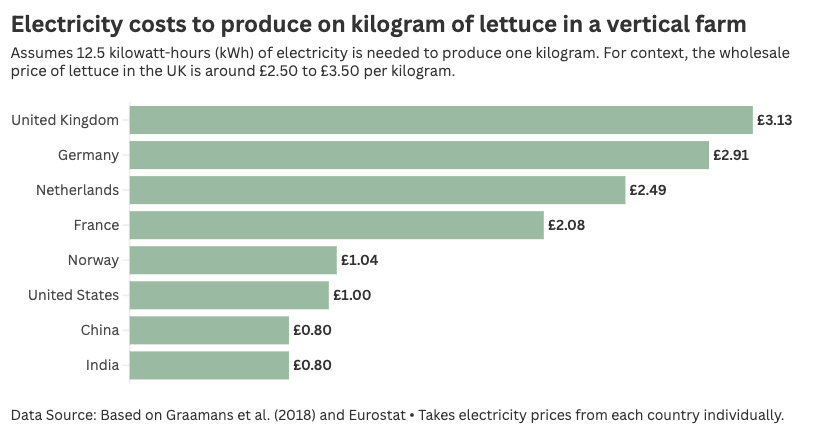

Now, the UK’s electricity is quite expensive. There are some countries — with cheap electricity — where the economics are much more promising.

Industrial electricity prices in the US can get as low as $0.10 per kWh, and in some states, even lower. American businesses might be able to produce a kilogram of lettuce using as little as $1.25 (£1) of electricity. That leaves several dollars or pounds per kilogram for other costs: capital, staffing, processing, etc.

Large parts of Asia — including some countries with lower electricity prices — offer even more competitive conditions. See the chart below, which provides additional context with examples from other regions.

So, there are places where the economics might work, and vertical farming for lettuce and greens could become profitable.

The economics of producing leafy microgreens — mostly herbs — can be even more favourable because they tend to fetch higher prices in the market.3

Another up-and-coming crop is strawberries. They’re also a good choice for vertical farming: small, with a fast lifecycle, and consumers are often willing to pay premium prices for freshness.

Strawberries are a popular choice in the UK; there are a number of companies working on this, such as FlexFarming, BerryWorld, Jones Food Company and DPS.

Vertical farming makes for an extremely expensive loaf of breadCereals — which provide most of the world’s calories — are not going to be produced in vertical farms any time soon.

One challenge is height: cereal crops tend to be tall, so you can’t stack as many shelves on top of one another.

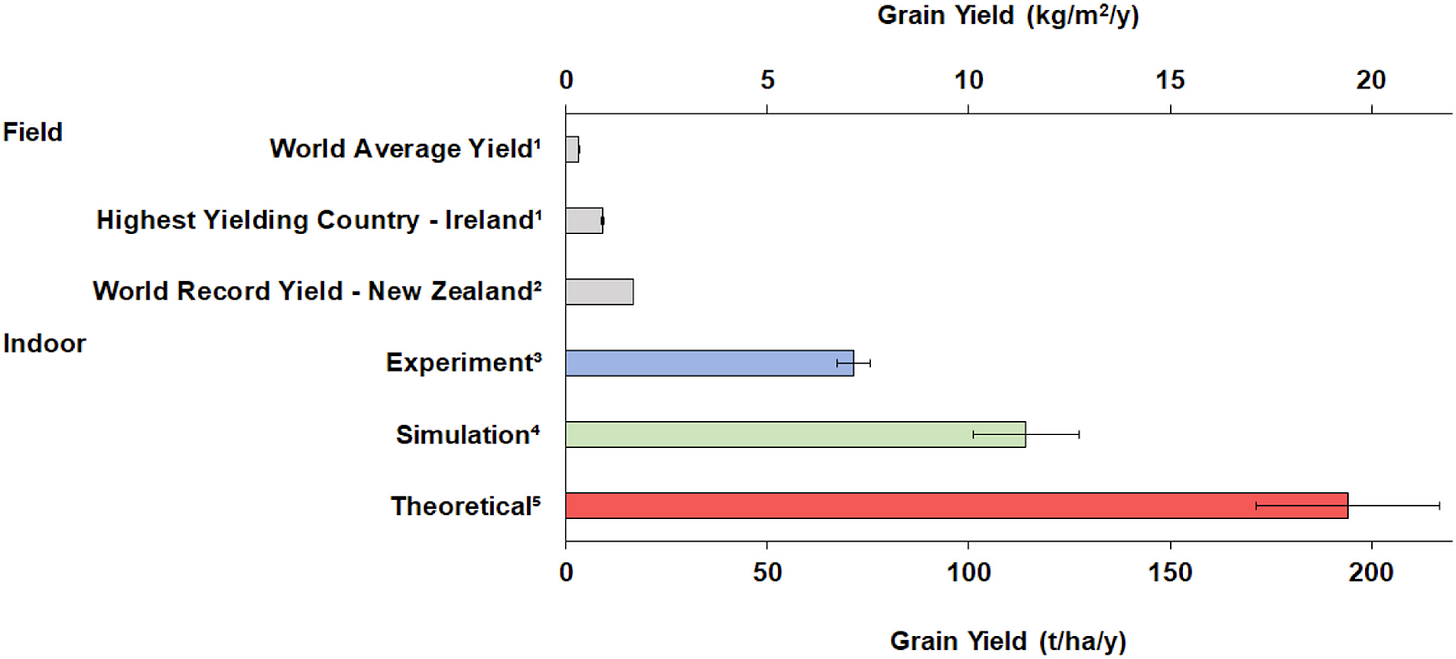

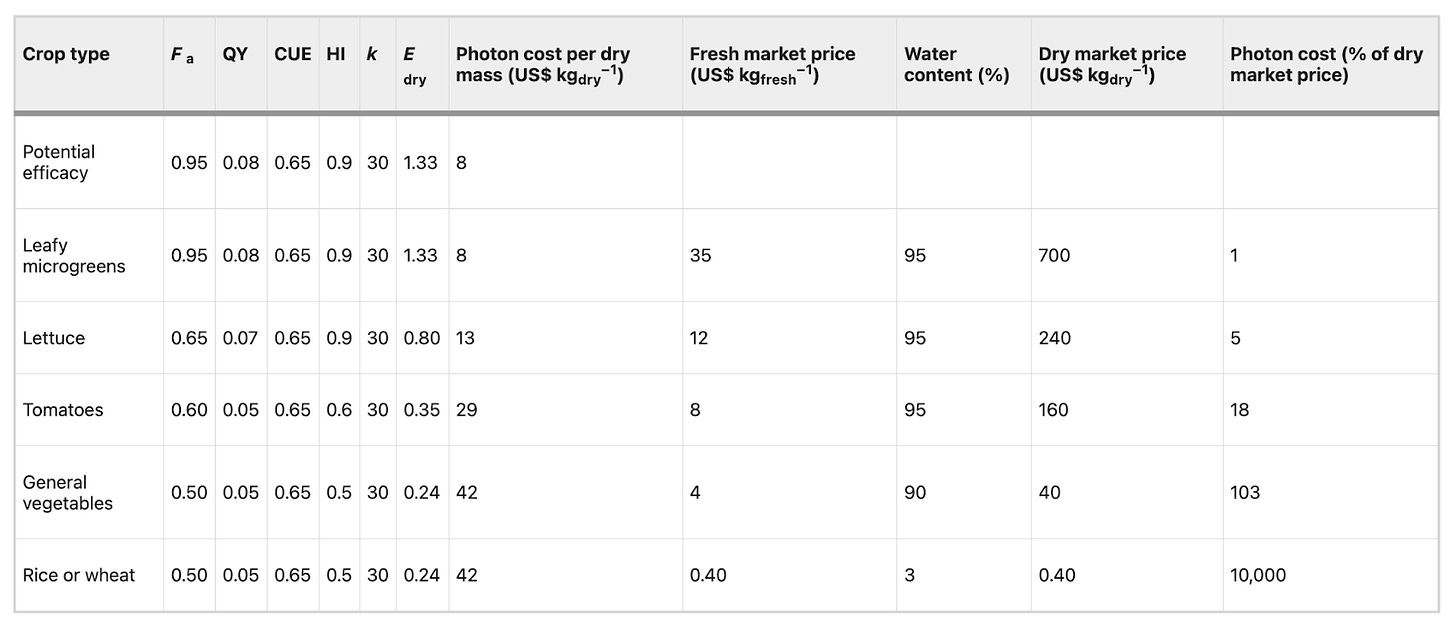

Nonetheless, small-scale experiments on wheat have recorded extremely high yields. A study published in PNAS estimates that indoor farming in controlled conditions has experimentally produced yields of 70 tonnes per hectare, with the potential to reach as high as 190 tonnes per hectare under optimal controlled conditions.4 See the chart below.

These yields are far higher than the global average of 3.7 tonnes per hectare, or even the maximum outdoor yield of 17 tonnes per hectare (set on a farm in New Zealand).

The authors estimate that the maximum theoretical yield in vertical farms could be as high as 1,940 tonnes per hectare — around 500 times the global average today. This assumes 10 shelves stacked on top of one another.

The land use — and food security — benefits would be immense. However, the problem is cost.

Cereals are cheap crops and tend to fetch very slim margins. In many countries, cereal production is not economically viable without subsidies.

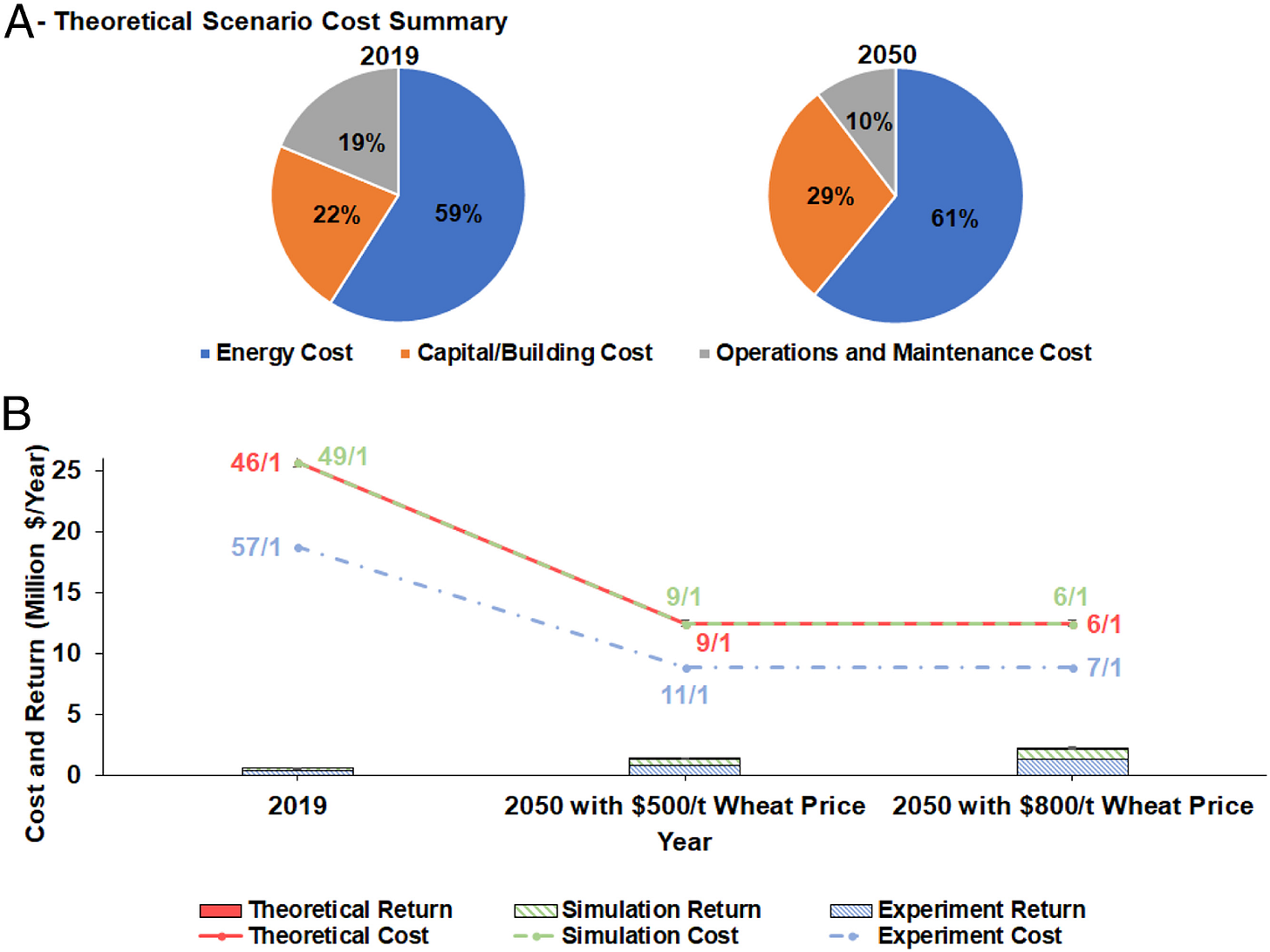

Based on 2019 wheat prices, the authors estimated that the cost-to-return ratio was around 50-to-1. In other words, investment costs — dominated by energy expenses — were 50 times higher than expected returns. And it assumed that electricity prices were much lower than in most countries today.

They also modelled potential returns for 2050, assuming much higher wheat prices and extremely low energy costs: 2 cents per kWh, based on the estimated cost of a solar-plus-storage system.5 Even in these optimistic scenarios — or pessimistic, if, like me, you think expensive wheat is a bad thing — vertical farms for cereals would still not be economically viable.

Another paper — published in Nature — estimated that lighting alone costs around 100 times the market price of wheat or rice.6 This study took reasonable energy costs of around $0.10 per kWh (which is similar to industrial costs in the US).

Without some crazy technological breakthrough, cereals are are going to be an outdoor-only crop for a long time.

Vertical farms are not always better for the climateVertical farming isn’t a free lunch when it comes to environmental impact. We’re trading energy use for land use. And if that energy isn’t entirely low-carbon, it will still have a carbon footprint.

As with many innovations that rely on electrification — such as electric cars, heat pumps, or electrified industrial processes — it’s useful to quantify the impact today while acknowledging that this can improve in the future as grids decarbonise.

A number of studies, conducting full life-cycle analyses, have found that vertical farms currently have a higher carbon footprint than conventional outdoor farming. One study, based in California, and the other in the Netherlands, both focused on lettuce production.

In the future, vertical farming systems could potentially run entirely on renewable energy, which would significantly reduce their carbon footprint. However, this might not always be enough to make them lower-carbon than outdoor farming. For example, the study in the Netherlands modelled a renewable energy scenario. While the carbon footprint gap narrowed, the vertical farm’s emissions still exceeded those of traditional outdoor farming.

Another consideration is whether vertical farming represents a “good use” of low-carbon energy that could be used to decarbonise other parts of the energy system instead. There’s no “right” answer here — only trade-offs — but it’s worth questioning whether the benefits of producing all our lettuce in vertical farms outweigh the opportunity cost of allocating low-carbon electricity to transport, heating, data centres, or industry.

Here’s a quick calculation to put this into perspective. I estimate that producing all the USA’s lettuce in vertical farms would require around 42 TWh of electricity.7 That’s 1% of total current generation.8 Now, lettuce is one of the least nutrient-dense foods out there. It’s basically mildly-flavoured water: minimal calories, and has very little micronutrients compared to other vegetables.

This raises an open question: do countries want to increase electricity demand by 1% to free up land used for lettuce production?

The future of vertical farmingLike many of the innovations and challenges I’ve written about recently, data sharing on the energy costs and financials of vertical farms is poor. Most of the data I’ve relied on has come from academic papers — often several years old. Maybe the fundamentals really are improving rapidly behind-the-scenes. But without companies sharing their data publicly, there’s no way to take that into account.

But like any technology, we shouldn’t view this as a static problem but a dynamic one: the efficiency of these systems will surely improve over the coming decades, so maybe we should be a bit more optimistic.

Haitz’s Law describes the historical improvements in the efficiency of LED lighting. Every decade, the cost per lumen has fallen about 10-fold, and the amount of light produced per LED increases 20-fold.

If these improvements continue, then prospects for vertical farming could dramatically improve a few decades from now. If combined with much cheaper electricity systems — which would, most likely, come from decentralised production rather than tapping into the grid — then I could see the economics shifting a lot.

There are, however, physical limits to the photosynthetic capacity of plants. Most crops convert just 1% to 6% of solar energy into biomass. The theoretical maximum is around 11%. That means the amount of kilograms of biomass you get per kWh of power has a floor. Even with highly skilled genetic engineering, the amount of lettuce, strawberries or wheat produced per kilowatt-hour is not going to increase by more than a factor of 10.

I think it’s totally plausible that vertical farms break through for the production of some premium fruits and vegetables. These farms could be comfortably profitable, and provide the long list of benefits I mentioned at the start. Whether we want to accept the trade-off of energy for land is then up to us.

But vertical farms are not going to supply calories in any meaningful way — and by meaningful, I mean more than a few percent. Proteins we can feasibly do indoors. Fats, too. Fruits and vegetables — which are mostly water — maybe. But carbohydrates are the one macronutrient that is much tougher to crack.